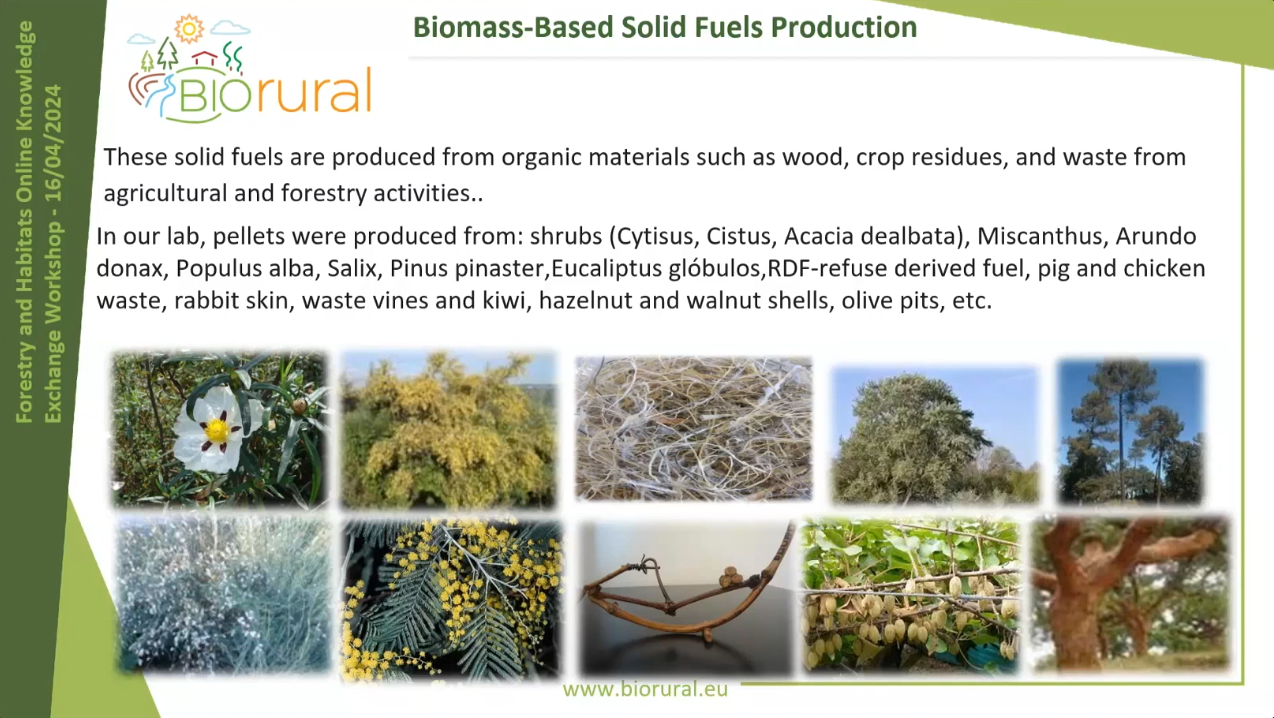

The focus of the presentation is on biomass direct combustion heat boilers. Juliana begins by explaining the basic principles of their operation, what types of fuels they utilize, leading up to how this technology will help transition to renewable feedstocks, like biomass. She briefly goes over the advantages and area of application of each technological category: biomass, natural gas, coal and oil fired boilers, and last, municipal solid waste boilers. Juliana then makes an overview of the European biomass boiler market, which she explains is expected to grow at a Compound Annual Growth Rate of 7.8% from 2024 until 2032, ending up at a projected market value of 20.1 billion dollars. This growth will be based on recent advances on emissions reduction, boiler efficiency and increased business and industry interest in bio-heat and electricity. An overview of the global biomass boiler market follows, based on the feedstocks, including woody biomass, agricultural waste, industrial waste, urban residues and others. She explains how increasing decarbonization efforts are expected to expand woody biomass technology uptake. Following, the challenges of such market growth are laid out: i) high initial investment costs, which can be addressed by financing schemes such as the Energy as a Service (EaaS) or other government incentives across the EU can help offset these expenses, ii) fuel availability, which is addressed by constructing more dependable and diverse supply chains to meet regional demands and ensure sustainability. Regarding the biomass value chain, Juliana makes breaks it down and elaborates on land use, biomass production, conversion, and end use. She mentions the main contributors of biomass: forestry, agriculture, marine biomass, as well as the various residues from various human activities. Then there is also mention on the role it plays in the wider bioeconomy, as well as aiding towards the creation of a circular economy. Modern biomass boilers are poised to play an important role in the wider bioeconomy cadre, so Juliana breaks down the technical characteristics and operation of a typical automatic SCIVEN biomass boiler to demonstrate its properties and capabilities compared to outdated systems. These systems are capable to replace natural gas boilers in terms of convenience due to modern automations, while offering a considerably lower cost of maintenance due to significantly less expensive feedstocks, even considering the time of the year as a factor, as demonstrated by a comparative analysis presented. The presentation closes with a virtual Q&A session where Juliana addressed some of the most commonly asked questions around biomass, bioheat, related technologies and the bio-based economy as an expert in the field, while also demonstrating SCIVEN’s principles and approach around it.